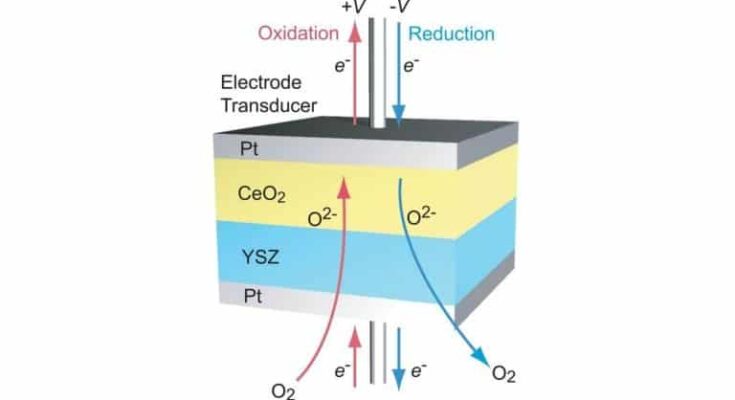

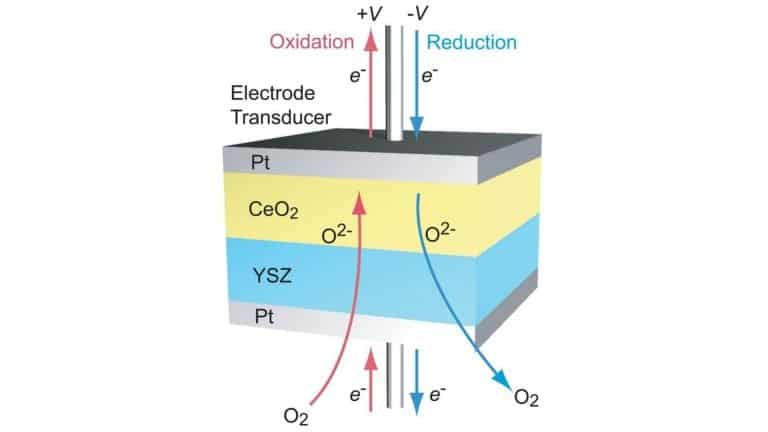

A group of scientists at Hokkaido University to Sapporo, Japanintroduced a new method to enhance the performance and stability of temperature switches. By working cerium oxide (CeO₂) as a material that works in the form of a thin film, these switches achieve an impressive thermal performance while reducing the environmental and economic costs of production. This presentation, led by Prof Hiromichi Ohtait marks an important step forward heat systemwhich aims to deal with energy waste and improve heat recovery methods.

Dealing with Energy Table by Thermal Changes

A staggering two-thirds of the energy produced by fossil fuels, such as coal and oil, is wasted as heat. Temperature changeswhich include thermal diodes and thermal transistorshelp restore this lost energy. By automatically controlling heat flow, these devices connect or disconnect heat paths between components, improving performance. renewable energy system and electronic heating devices.

Compared to thermoelectric energy conversion technologywith a low energy conversion, thermal switches provide a high temperature recovery method. They are also important for advanced technology, such as thermal shutters and infrared temperature control in the shows, which highlights their flexibility.

Main Benefits of Cerium Oxide

Cerium oxide was chosen as the active material for its functionality and high performance. Unlike the traditional materials used in thermal switches, which are often rare and environmentally costly at the source, cerium oxide is:

- It is abundant and eco-friendly: Easy to find and economical in my opinion.

- It works well: It provides high thermal conductivity compared to its counterparts.

The research group showed that switches based on cerium-oxide significantly outperform conventional devices while maintaining low production costs. This makes them a viable solution for a wide range of energy systems.

Excellent Performance Benefits

The heat exchangers developed at Hokkaido University set new standards in performance:

| Parameter | Quality | Important |

|---|---|---|

| On/off thermal conductivity ratio | 5.8 | It exhibits a high degree of temperature control. |

| Thermal conductivity range | 2.2 W/m·K (outdoor) to 12.5 W/m·K (on-site) | It shows the ability to change temperature. |

| Lasting | Preserved activity over 100 reduction/oxidation pockets | It proves reliable for long-term use in active conditions. |

These benefits, highlighted in the press release by Professor Hiromichi Ohtaverify the ability of switches based on cerium-oxide to replace existing technologies with more durable, efficient and sustainable alternatives.

Applications and Way Forward

Cerium-oxide-based thermal switches are already being used in key areas, including:

- Electronic cooling systems: Improving thermal management of consumer and industrial electronics.

- Renewable energy platforms: Optimizing energy recovery in a sustainable power system.

Future developments may extend their use to specialized systems, such as high performance thermal shutters and temperature control methods with advanced display technology. These proposals highlight the role of sustainable materials in driving progress in various sectors, from consumer technology to industrial processes.

The results of the research are published in the journal Advances in Science.

Do you have any ideas? Share your thoughts in the comments

Enjoyed this article? Subscribe to our free Newsletter for great stories, exclusive content, and the latest news

#Japanese #Scientists #Develop #Thermal #Converters #Sustainable #Materials